- Home

- Capability

- Centrifugal Casting

Centrifugal Casting Products

The centrifugal casting method is to produce pipes by pouring molten metal into a rapidly spinning cylindrical mold in which centrifugal force from the rotation exerts pressure on the molten metal. It can do vertical centrifugal casting and horizontal centrifugal casting, mainly used to cast various tubular/ring/cylindrical castings. Centrifugal casting can provide castings with good quality, no pores and impurities. The maximum outer diameter of castings that STINCO can produce is 2.5 meters.

Centrifugal Casting Equipment

Vertical centrifugal casting machine (12 sets)

| Dimension range : | O.D. 105mm - 355mm ; length 300-550mm | 6 sets |

| Dimension range : | O.D. 255mm - 660mm ; length 350-650mm | 3 sets |

| Dimension range : | O.D. 345mm - 1200mm ; length 350-750mm | 1 set |

| Dimension range : | O.D. 800mm - 1700mm ; length 500mm | 1 set |

| Dimension range : | O.D. 1500mm - 2700mm ; length 500mm | 1 set |

Horizontal centrifugal casting machine (in purchasing) (2 sets)

| Dimension range : | O.D. 135mm - 280mm ; length 2000mm | 1 set |

| Dimension range : | O.D. 300mm - 580mm ; length 1500mm | 1 set |

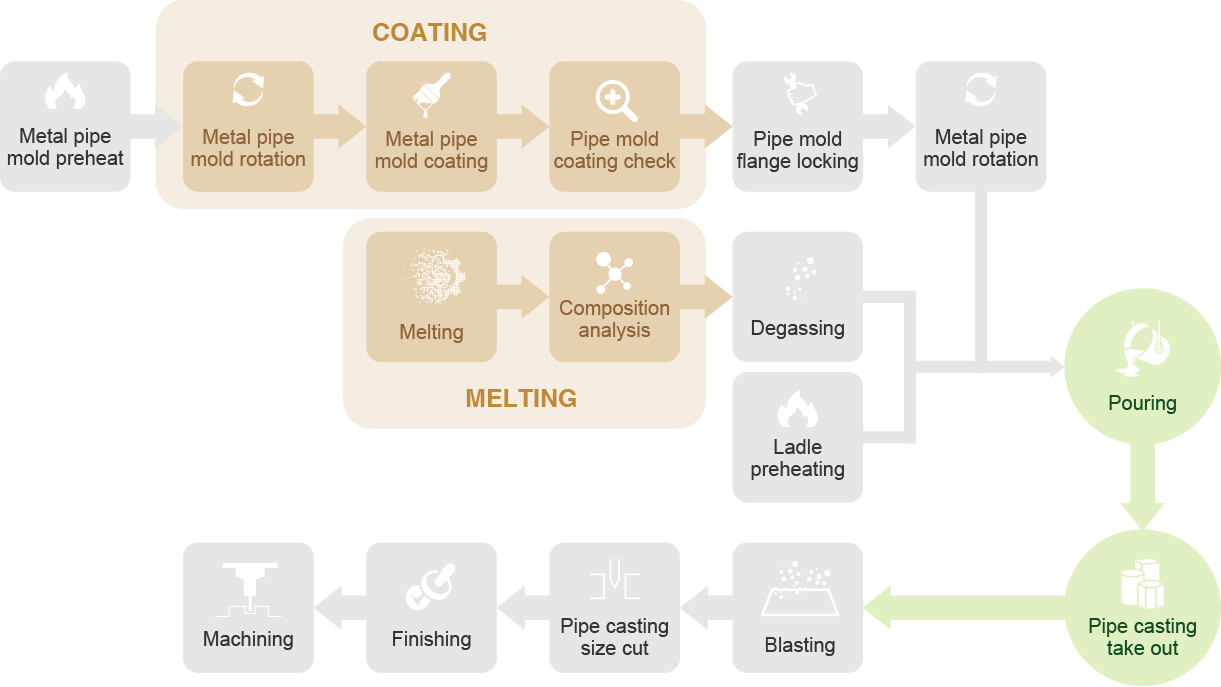

Centrifugal Casting Process