- Home

- Capability

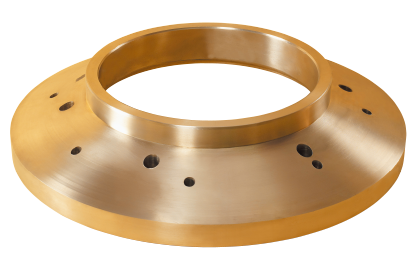

The centrifugal casting method is to produce pipes by pouring molten metal into a rapidly spinning cylindrical mold in which centrifugal force from the rotation exerts pressure on the molten metal. It can do vertical centrifugal casting and horizontal centrifugal casting, mainly used to cast various tubular/ring/cylindrical castings. Centrifugal casting can provide castings with good quality, no pores and impurities. The maximum outer diameter of castings that STINCO can produce is 2.5 meters.

...more >Mechanise moulding is a kind of sand casting process, also known as green sand mold process. The mold is made of a mixture of sand/water/clay and is poured molten metal into it to form a casting. Mechanise moulding is capable of providing castings with finer surface and is mainly suitable for small workpieces with a large amount.

...more >Furan casting is a kind of sand casting process, widely used in foundries. This method is using furan resin hardener as a binder and mixing with catalyst in a proper proportion to produce furan sand mold. Furan casting can provide good surface quality, smooth surface finish and good dimensional tolerance, which is mainly adapted for complex large castings. The largest workpiece STINCO can produce is max. 10 tons per piece.

...more >Gravity casting is so called permanent mold casting. The permanent mold usually is made of metal with a higher melting point and can be reused. Gravity casting method is using the earth's gravity to pour molten metal into the mold and can provide good casting structure, surface roughness and good dimensional accuracy. STINCO mainly uses gravity casting to make red copper products, such as heavy electrical parts and conductive parts.

...more >Continuous casting is to pour molten metal into a horizontal or vertical mold with the ability for rapidly chilling the metal to the point of solidification, which is the process to make molten metal into semi-finished casting, so continuous casting is also called strand casting. It can not only promote production efficiency but also ensure uniform structure, good mechanical properties due to rapid cooling. STINCO provides bar/tube materials as semi-finishing products and/or machined products by CNC or forging.

...more >This casting method is a process of passing a metal ingot through a pair of rollers and rolling it into shape, which is called “rolling”. If the temperature of the metal material exceeds the recrystallization temperature, the metal processing procedure is called “hot rolling”. Hot rolling is mainly used to produce sheet metal parts or products with simple cross-sections, such as stamping parts, embossed copper molds (ex. shoe mold embossing), and branded copper molds. At present, the copper plate materials produced by STINCO include brass and aluminum bronze, available in 450mm x 450mm max. with 6mm min. thickness.

...more >Lost-wax casting is an ancient and widely used metal casting technique, also known as precision casting or investment casting. In this casting process, a wax model is first created, and then coated with a heat-resistant refractory material to form a mold. The mold is heated to melt or vaporize the wax model, leaving behind a cavity. Finally, molten metal is poured into the cavity to create the casting. Lost-wax casting is commonly employed for casting highly detailed and intricate metal parts such as mechanical components and sculptural artworks. This method allows for the preservation of intricate details from the wax model, producing complex and high-precision castings. Additionally, it enables the reduction of machining, cost savings, and facilitates large-scale production.

...more >