- Home

- Capability

- Hot Rolling Copper Plates

Hot Rolling Copper Plates

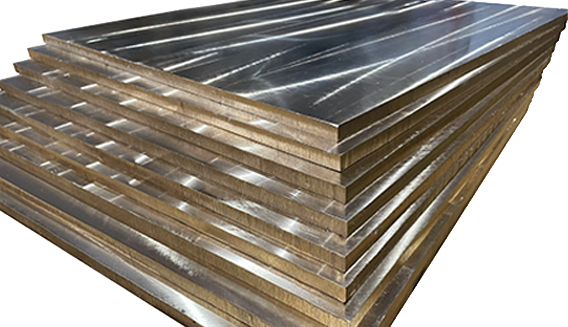

This casting method is a process of passing a metal ingot through a pair of rollers and rolling it into shape, which is called “rolling”. If the temperature of the metal material exceeds the recrystallization temperature, the metal processing procedure is called “hot rolling”. Hot rolling is mainly used to produce sheet metal parts or products with simple cross-sections, such as stamping parts, embossed copper molds (ex. shoe mold embossing), and branded copper molds. At present, the copper plate materials produced by STINCO include brass and aluminum bronze, available in 500mm x 500mm max. with 6mm min. thickness.

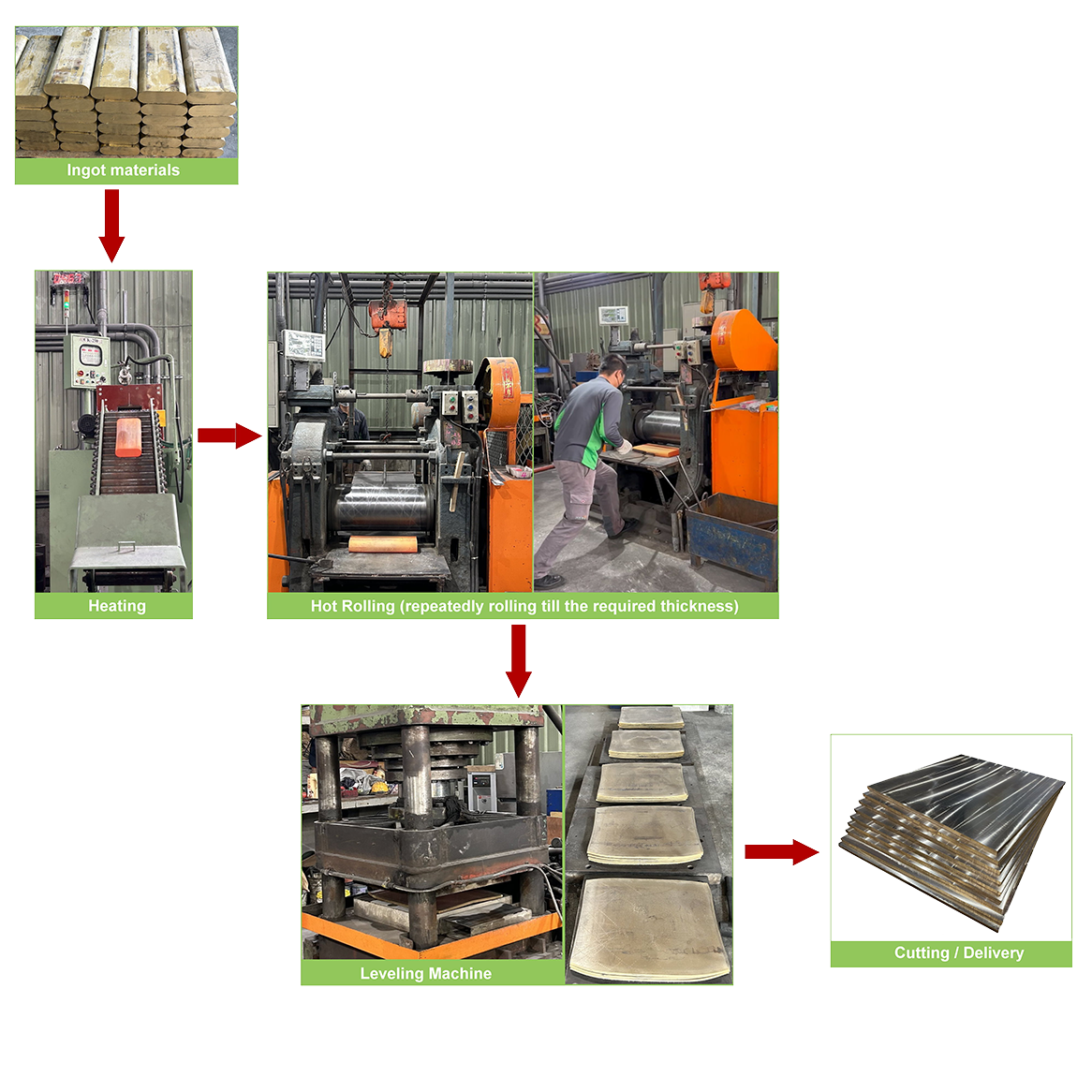

Hot Rolling Process